The A325 Tc Bolts PDFs

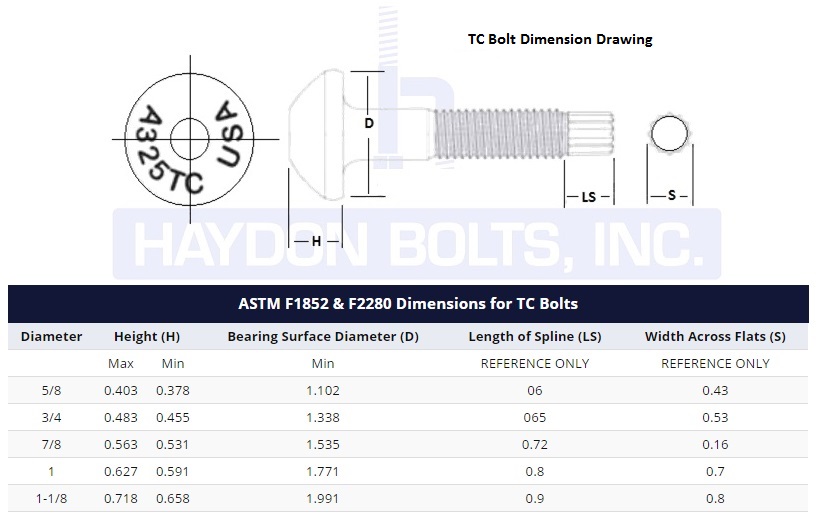

Stress control bolts, TC Bolts or "Twist-Off" bolts, have become one of the world's most widely used technique to tension high strength structural bolts, as they can be used in practically all steelwork connections. As a high strength tension control bolt supplier, AFT provides ASTM A 325 and A 490 TC bolts in bolt sizes varying from 5/8" approximately 1" and lengths from 1-1/2" approximately 7".

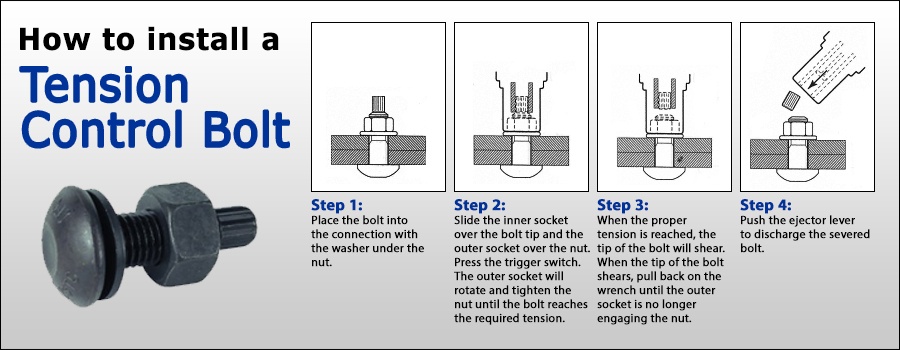

The stress control bolt consists of a three-piece fastening system with 1) a round head bolt with a truncated, flat surface location at the top of the bolt, and a 24-sided pointer which extends from the opposite end. The pointer is calibrated to shear off when the appropriate stress is used.

This technique was developed in the 1950s in an effort to offer an approach of stress control which would overcome the unreliability of torque ending up being totally valued. To be achieved effectively, the plies in a joint or connection have to be first of all in firm contact and after that some initial tension has actually to be caused into each bolt.

On many connections specifically with multiple plies, of heavy steel with big diameter bolts, this would not be nearly adequate force to accomplish these 2 preliminary objectives. Following this preliminary step, the bolts have to be matched significant to show that after tight tightening the ideal amount of rotation was applied.

These turning requirements vary from 1/3rd of a turn, a turn, 2/3 of a turn, 5/6 of a rely on one complete turn. When a bolt length surpasses more than 12 times the diameter, in some way the needed turn needs to be verified, although the average bolt tension calibrator, if available on the job website, would require considerable adjustment with back up plates to evaluate for the right degree of rotation.

Alternatively, a little corrosion or dryness triggers the nuts to freeze or lock up making the conclusion rotation in fact not possible. In fact match marking is seldom utilized and in the U.S.A. specifically examination goes back to the discredited torque wrench. If the Part Turn method or Turn- of- Nut is dealt with as intended by the majority of codes, it is more pricey and time consuming than utilizing Turna Sure DTIs.

Examine This Report on Galvanized Tension Control Bolts

Keep in mind: In over thirty years of job website experience, match marking is rarely seen being properly carried out, let alone constant examination for preliminary snug tightening up. If turn-of-nut was applied correctly, commencing, as it should, from some preliminary bolt stress, the bolts are normally taken to beyond their yield point. This requires the maximum effort in turning forces applied.

Fact- DTIs only need the forces needed to appropriately set up each bolt. Our conviction is that if Turn-of Nut is declared to take less effort (torque), then this is clearly admitting to brief cuts, and when allowed therefore; slack bolts will be the outcome! Service: Specify Turna Sure DTIs . It is now nearly difficult to mess up Turna Sure DTIs.

Stress Control Bolts, TC Bolts or Twist Off Bolts are now the most popular choice in high-strength structural bolting and formally acknowledged by the AISC (American Institute of Steel Building) and the RCSC (Research Study Council on Structural Connections) as an authorized installation approach. A Tension Control Bolts consists of 1 bolt, 1 nut and 1 washer, pre-assembled and there for they are revealed, 1 lot number, on the accreditation documentation.

They are set up with a specialized electrical shear wrench that has an outer socket that turns the nut counterclockwise, while getting the spline with the inner socket turning it clockwise. When the appropriate stress level has been attained the spline snaps off giving you a visual indication of appropriate setup.

Due to the fact that of this proprietary lubrication, it is NOT permissible to re-lubricated TC bolts, in the field, only the manufacture of a TC bolt can re-lubricate a TC assembly. Specification: A 325/F 1852 & A 490/F 2280 Finish: Type-1, Type-3 & Mechanical Galvanized Ordering Information NOTE 2-- Bolts are often detailed with names such as A 325 HS, A 325 SC, A 325 X or A 490 N.

this post you could try here official statement